Maintenance Guide for Commercial Playground Equipment

Essential Maintenance Principles for Safe Play Spaces

Commercial playground equipment requires a proactive maintenance program that balances safety, appearance, and lifecycle costs. Whether you manage an indoor playground, a trampoline park, or an outdoor amusement area, systematic inspections, timely repairs, and clear documentation reduce injury risk, protect liability, and extend asset life. This guide outlines practical maintenance routines, inspection frequency, common failure modes, and recordkeeping best practices tailored to commercial playground equipment.

Why Regular Inspection of Commercial Playground Equipment Matters

Regular inspections are the foundation of an effective maintenance program for commercial playground equipment. Inspections catch wear and hazards—broken fasteners, sharp edges, worn surfacing—before they cause injury. According to the U.S. Consumer Product Safety Commission (CPSC), properly maintained playgrounds dramatically reduce the number and severity of incidents. A documented inspection routine also supports compliance with standards (e.g., ASTM, EN) and demonstrates due diligence to insurers and regulators.

Types of Inspections for Commercial Playground Equipment

Inspections are tiered by depth and frequency:

- Daily/Operational Checks: Quick visual checks to remove obvious hazards and ensure supervision resources are in place.

- Weekly/Functional Inspections: Hands-on tests of movable parts, basic surfacing checks, and cleaning.

- Monthly/Detailed Inspections: Tightening hardware, checking wear points, measuring surfacing impact attenuation, and documenting findings.

- Annual/Comprehensive Inspections: Performed by trained staff or certified inspectors to evaluate structure integrity, corrosion, and compliance to standards.

Routine Maintenance Checklist for Commercial Playground Equipment

Consistent, routine maintenance prevents small problems from becoming hazards. The checklist below focuses on common commercial playground equipment components: structures, surfacing, fastening systems, mechanical parts, and soft goods.

- Structural Components: Check for rust, cracks, splinters, or breaks; verify anchors and foundations.

- Fasteners and Connections: Tighten bolts, replace missing or sheared fasteners, verify locking devices.

- Surfacing: Remove debris, verify depth and coverage of loose-fill materials, inspect poured-in-place or rubber tiles for tears or uplift.

- Mechanical Elements: Test swings, springs, rotating elements for wear and proper function.

- Padded and Soft Components: Repair torn vinyl, replace padding that no longer compresses properly.

- Hygiene and Cleanliness: Clean high-touch areas, disinfect as needed (especially for indoor commercial playground equipment).

Inspection Frequency Table for Commercial Playground Equipment

Use the table below as a baseline schedule. Adjust frequency based on usage intensity, age of equipment, and environmental conditions.

| Inspection Type | Frequency | Key Tasks |

|---|---|---|

| Daily/Operational | Daily (or every opening) | Visual hazard removal, gate/door checks, obvious damage removal |

| Weekly/Functional | Weekly | Test swings/rotating parts, surfacing debris removal, minor repairs |

| Monthly/Detailed | Monthly | Tighten hardware, check impact-attenuating surfacing depth, lubricate moving parts |

| Annual/Comprehensive | Annually | Structural integrity assessment, corrosion inspection, record review, third-party audit if required |

Surfacing Maintenance for Commercial Playground Equipment

Impact-attenuating surfacing is often the most critical element in injury prevention. Different surfacing materials require different maintenance:

- Loose-fill (wood chips, engineered wood fiber): Rake regularly to maintain even coverage; measure depth quarterly and replenish to maintain minimum fall height requirements stated by the equipment manufacturer and applicable standards.

- Rubber mulch: Remove foreign debris and replenish as needed; monitor for compaction and drainage issues.

- Poured-in-place and rubber tiles: Inspect for cracks, edge uplift, and drainage. Repair tears quickly and verify drainage to prevent freeze/thaw damage in cold climates.

Measure and record surfacing depths. Manufacturers and standards specify minimum thickness for given fall heights—documenting measurements shows due diligence in safety management.

Cleaning, Sanitization and Indoor Considerations for Commercial Playground Equipment

Indoor commercial playground equipment requires additional attention to hygiene, air quality, and wear from high use. Establish cleaning protocols tailored to materials (vinyl, plastic, foam, metal). Use manufacturer-approved cleaners to avoid material degradation. For high-touch zones (ball pits, tunnels, slides), schedule deep cleaning and disinfection regularly; ball pits may require full ball turnover and sanitization every 1–3 months depending on usage and local health guidance.

Hardware, Fasteners and Corrosion Control for Commercial Playground Equipment

Corrosion and loosening fasteners are common failure points. Use these best practices:

- Use tamper-resistant and grade-appropriate fasteners specified by the manufacturer.

- Replace corroded hardware immediately and protect cut edges with paint or sealants appropriate for playground use.

- Document torque values if specified, and use calibrated tools for re-tightening critical connections.

Recordkeeping, Documentation and Compliance for Commercial Playground Equipment

Documentation is essential for safety management and legal protection. Maintain records of inspections, repairs, parts replaced, and supplier communications. Recommended items to keep in a digital or hard-copy maintenance log:

- Inspection checklists with dates and inspector names

- Repair orders and parts invoices

- Incident reports

- Manufacturer manuals and warranty documents

- Third-party inspection or certification reports

These logs support compliance with local regulations and help identify recurring issues to inform capital planning.

Staff Training and Outsourcing Maintenance for Commercial Playground Equipment

Well-trained staff reduce risk. Create a training curriculum that covers daily checks, basic repairs, safe lifting and tool use, hazard recognition, and how to escalate issues. For specialized tasks—structural repairs, surfacing replacement, or complex mechanical repairs—work with certified playground maintenance contractors or the equipment manufacturer to ensure work meets design specifications and does not void warranties.

Budgeting and Lifecycle Management for Commercial Playground Equipment

Plan budgets across three categories: routine maintenance, medium-term component replacement (3–7 years), and full replacement (10–20+ years depending on materials and use). A lifecycle plan based on usage data and maintenance history helps prioritize upgrades and capital investments. Allocate a percentage of revenue (commonly 2–5% for high-use facilities) to maintenance and replacement reserves—adjust according to actual wear rates and incident history.

Emergency Repairs and Spare Parts Strategy for Commercial Playground Equipment

Keep a basic spare parts inventory for common wear items: fasteners, swing seats and chains, replacement bolts, padding material, and surfacing replenishment. For rapid response, document trusted suppliers and local contractors able to perform emergency repairs. Establish service-level agreements (SLAs) for response times to reduce downtime and liability exposure.

Manufacturer Spotlight: Guangzhou Feifan Amusement Equipment and How Manufacturer Support Improves Maintenance

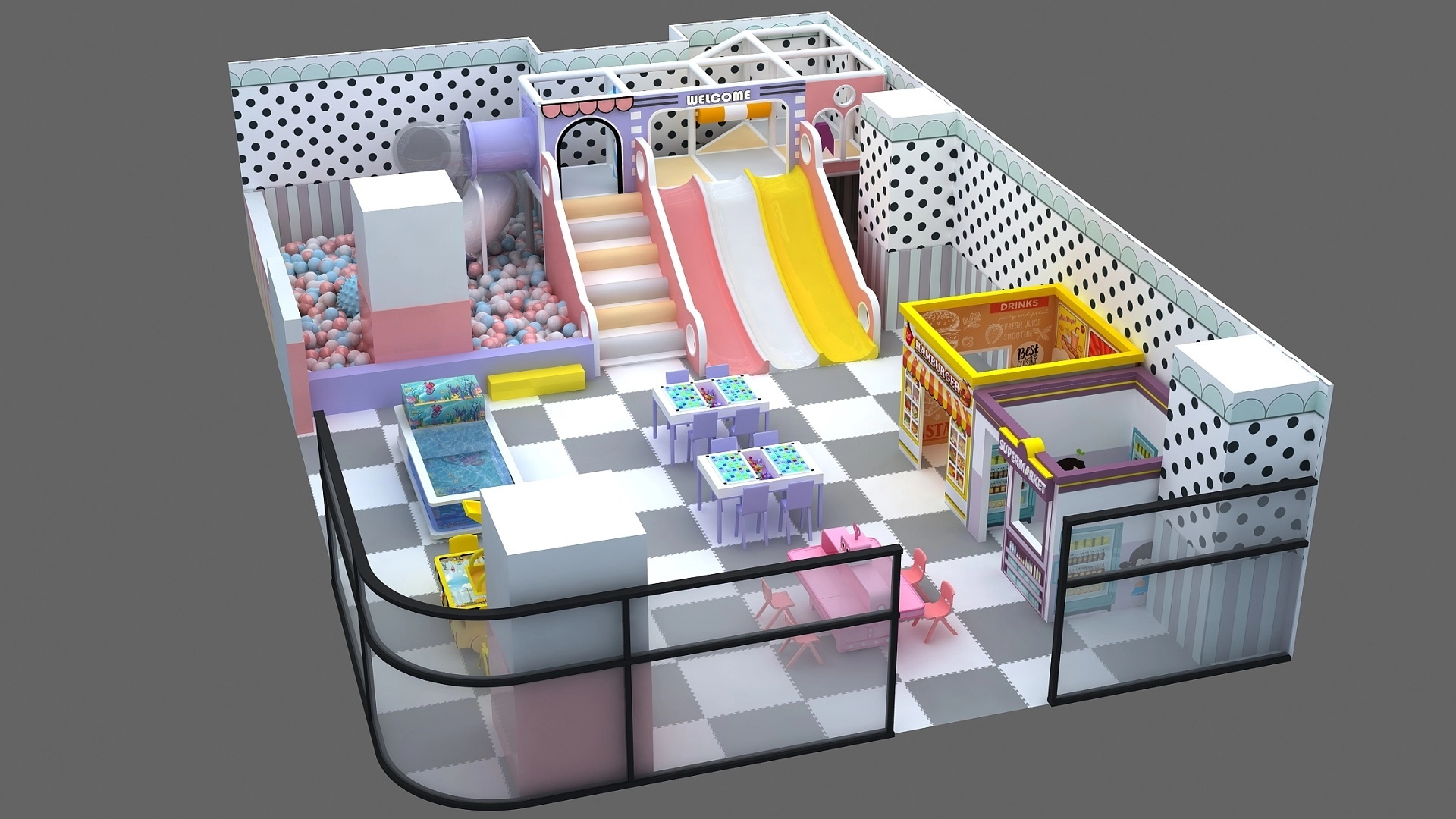

Choosing an experienced manufacturer simplifies long-term maintenance. Guangzhou Feifan Amusement Equipment Co., Ltd. was established in 2017. We are a comprehensive indoor playground equipment manufacturer that integrates design, research and development, production, sales, and service. And we have a modern factory building of 6400m² and a 5800 m² office building. Our company's main products include indoor playgrounds, trampoline park equipment, and outdoor amusement equipment. We are committed to creating high-end indoor and outdoor children's amusement equipment and enjoy a high reputation both at home and abroad. We look forward to working together with customers to create a better childhood!

FEI FAN is committed to becoming a global leader in the children's play equipment industry, with a core belief in creating joyful, safe, and imaginative spaces for every child. Through professional design, high-quality manufacturing, and fully customized services, we deliver efficient, one-stop indoor playground solutions for clients around the world. We are not just manufacturers—we are creators of joyful experiences, enablers of parent-child interaction, and companions in child development.

FEI FAN Advantages for Commercial Playground Equipment Operators

- Integrated service model: design, R&D, production, sales and after-sales service reduce single-point failures and simplify sourcing of spare parts and documentation.

- Large modern facilities (6400 m² factory, 5800 m² office) enable consistent quality control and production capacity for replacement components and custom orders.

- Product portfolio focused on indoor playgrounds, trampoline parks, and indoor theme parks allows a single-provider approach for multi-attraction venues.

- Customization and safety-focused design help operators meet regional standards and reduce retrofit costs later.

Selecting Materials and Designs that Simplify Maintenance of Commercial Playground Equipment

When procuring commercial playground equipment, choose materials and design features that ease maintenance: powder-coated galvanized steel to resist corrosion, modular components for quick replacement, UV-stable plastics for outdoor use, and sealed fasteners or tamper-resistant hardware. Request maintenance manuals, recommended spare parts lists, and expected service intervals from the manufacturer at purchase.

Common Failure Modes and How to Prevent Them on Commercial Playground Equipment

Understanding common failure modes informs targeted maintenance:

- Fastener fatigue and loosening: use proper torque, thread-locking where appropriate, and periodic re-torquing.

- Surface wear and compaction: replenish loose-fill surfacing and repair resilient surfacing promptly.

- Corrosion in wet or coastal environments: use higher-grade coatings and inspect more frequently.

- Mechanical wear (bearings, swivel points): schedule lubrication and replace worn bearings before seizure.

- Hygiene-related deterioration (indoor play): implement strict cleaning cycles and material-friendly disinfectants.

Practical Sample Maintenance Schedule for a Mid-Sized Indoor Commercial Playground Equipment Facility

Below is a sample schedule you can adapt to your facility size and usage:

- Daily: Quick walkthrough, clear debris, check gates and emergency exits.

- Weekly: Clean high-touch areas, inspect soft surfacing and padding, test swing and trampoline connections.

- Monthly: Measure surfacing depth, tighten visible fasteners, document findings.

- Quarterly: Deep clean ball pits and soft zones, replace worn soft elements, check HVAC and ventilation for indoor safety.

- Annually: Third-party structural inspection, review maintenance logs, update risk assessments and insurance documentation.

FAQ — Frequently Asked Questions about Maintenance for Commercial Playground Equipment

- How often should commercial playground equipment be inspected?

At minimum: daily operational checks, weekly functional checks, monthly detailed inspections, and an annual comprehensive inspection. High-use venues may require more frequent inspections.

- Who should perform comprehensive inspections?

Comprehensive inspections should be performed by trained staff or certified third-party inspectors familiar with playground standards (ASTM F1487, EN 1176, local codes).

- What surfacing depth is required under commercial playground equipment?

Required depths depend on fall height and surfacing type. Refer to your equipment manufacturer and recognized standards (CPSC guidance, ASTM, EN 1176) for exact specifications and document measurements regularly.

- How should I manage maintenance records for liability protection?

Keep dated inspection reports, repair orders, parts receipts, incident reports, and manufacturer communications in a central file (digital backups recommended) to demonstrate due diligence.

- When should parts be replaced instead of repaired?

Replace parts when structural integrity is compromised, corrosion has reduced material strength, padding no longer meets impact attenuation properties, or if repairs are temporary fixes that might fail under expected loads.

- Can I perform maintenance in-house or should I use certified contractors?

Minor cleaning and tightening can be in-house if staff are trained. Structural repairs, major surfacing work, or warranty-covered services should be by the manufacturer or certified contractors to maintain compliance and avoid voiding warranties.

Contact & Next Steps — Get Professional Support for Your Commercial Playground Equipment

If you operate or plan to open a commercial playground, trampoline park, or indoor theme park and want maintenance planning, spare parts, or a turnkey solution, consider partnering with an experienced manufacturer like Guangzhou Feifan Amusement Equipment Co., Ltd. For consultations, customized maintenance plans, or to view product catalogs (indoor playground, trampoline park equipment, Indoor Theme Park solutions), contact your equipment provider or reach out to FEI FAN to discuss one-stop solutions tailored to your venue.

References and Further Reading

- U.S. Consumer Product Safety Commission — Playground Safety: https://www.cpsc.gov/Safety-Education/Safety-Education-Centers/Playgrounds (accessed 2025-12-22)

- Playground Safety (Wikipedia) — Standards overview and history: https://en.wikipedia.org/wiki/Playground_safety (accessed 2025-12-22)

- International Play Equipment Manufacturers Association (IPEMA): https://ipema.org/ (accessed 2025-12-22)

- EN 1176 Playground Equipment and Surfacing (overview): https://en1176.com/ (accessed 2025-12-22)

- Guangzhou Feifan Amusement Equipment Co., Ltd. — company information provided by client (accessed 2025-12-22)

Repair and Replacement of Playground Parts

Indoor Playground Themes That Boost Attendance and Revenue: Practical Ideas and Strategies

Top Indoor Playground Equipment Trends in 2025

Designing Themed Indoor Playground Equipment

Indoor Playgrounds Trampoline Parks

Do you provide international installation and after-sales support?

Yes, we offer on-site installation guidance, professional teams in many regions, and long-term after-sales services worldwide.

How long does it take to complete a project?

Depending on project size, it typically takes 4–10 weeks from design to delivery and installation.

For Products

How many square meters should we have to start an indoor playground ?

As usual,It is around in 50-500 square meters,For a large commercial center , it is about 500-2000 square meters.

Shopping MallsRetail Centers

How do your amusement areas benefit shopping malls?

They attract more families, increase dwell time, boost customer loyalty, and enhance overall mall revenue.

Schools Educational Institutions

Can you provide educational-themed playgrounds?

Yes, we create learning-based play concepts, such as alphabet walls, math games, and science-themed playgrounds.

Get in touch

Let’s Build Your Dream Indoor Playground Together

Thank you for your interest in our products and services!

We’re dedicated to providing you with the best possible support and solutions for your needs.

© 2025 Feifan Amusement Equipment. All Rights Reserved.

Scan QR Code

Scan QR Code

Indoor Soft Playground

Whatsapp: +8619068970573

Scan QR Code