Materials and Durability of Commercial Playground Equipment

Understanding Materials for Commercial Playgrounds

Why material choice matters for commercial playground equipment

Choosing the right materials for commercial playground equipment is foundational to safety, longevity, maintenance cost, and user experience. Operators, designers, and buyers must balance structural strength, weather resistance, impact performance, fire and chemical resistance, aesthetics, and life-cycle costs. Materials determine how equipment meets regulatory standards (ASTM, CPSC, EN 1176), withstands heavy public use, and how often repair and replacement will be needed.

Structural metals: steel and aluminum in commercial playground equipment

Metals form the skeleton of most commercial playground equipment. Mild steel (typically ASTM A36/A500 grade or equivalent) and galvanized steel are common for load-bearing posts and frames because of their high tensile strength and cost-effectiveness. Stainless steel (304/316) sees use in high-wear, vandal-prone, or coastal applications for superior corrosion resistance. Aluminum is chosen when weight and corrosion resistance are priorities, although it has lower stiffness than steel and can require larger sections.

Key considerations for metals:

- Corrosion protection: hot-dip galvanizing, zinc electroplating, and powder coating significantly extend service life. Hot-dip galvanizing per ASTM A123 offers thick, durable coverage suitable for outdoor installations.

- Fatigue and welding: structural connections must be engineered to avoid stress concentrators; use gussets and continuous welds evaluated by qualified fabricators.

- Maintenance: periodic inspection of coatings and touch-up painting reduces rust propagation.

Plastics and composites: HDPE, rotomolded plastics, and fiberglass for component durability

High-density polyethylene (HDPE) and rotomolded plastics are widely used for slides, panels, and decorative elements due to UV-stability, impact resistance, and color longevity. HDPE resists cracking and splintering compared to fiberglass-reinforced plastics (FRP) in many contexts, though FRP can offer superior stiffness for some themed elements.

Performance factors:

- UV stabilizers and pigments extend color life—look for UV-stable HDPE with additives per manufacturer datasheets.

- Thermal behavior: plastics can expand/contract in temperature; design tolerances and fastening methods must accommodate movement.

- Surface slip resistance and fire ratings should be checked for enclosed structures and components near seating or concession areas.

Elastomers and safety surfacing: rubber, EPDM, and poured-in-place systems

Impact-attenuating surfacing is essential for commercial playground equipment to reduce head injury risks. Common surfacing materials include poured-in-place (PIP) rubber (SBR or EPDM granules bound with polyurethane), rubber tiles, and engineered wood fiber (EWF).

Comparative points for surfacing:

- HIC and fall height: PIP and rubber tiles can be engineered to meet fall height requirements specified by ASTM F1292/CPSC guidance.

- Maintenance and drainage: EWF is inexpensive but requires replenishment and has drainage/compaction concerns; PIP provides durable, accessible surfaces but requires professional installation.

- Heat retention: darker rubber surfaces can become hot in direct sun—EPDM offers better color options and slightly lower heat absorption.

Fasteners, connectors, and coatings: invisible lifelines for longevity

Fasteners and surface coatings are critical to how long equipment lasts in the field. Stainless steel fasteners (304 or 316 depending on environment) minimize galvanic corrosion and seizing. Proprietary tamper-resistant hardware increases safety in public facilities.

Coatings and treatments include:

- Powder coating: provides thick, durable color layers; ensure proper surface preparation and chromate-free primers to improve adhesion.

- Hot-dip galvanization: best for buried or ground-contact posts; sometimes combined with powder coat for aesthetics and double-layer protection.

- Anti-graffiti or UV sealants: for high-traffic urban environments where appearance preservation matters.

Wood and engineered timber: when aesthetics meet maintenance

Treated lumber and engineered timbers (glu-lam) can be used for themed zones where natural appearance is prioritized. However, commercial playground equipment using wood requires a rigorous maintenance plan: periodic sealing, checking for rot, splintering, and insect damage. Many commercial operators favor synthetic materials due to lower life-cycle maintenance costs.

Comparing materials: durability, cost, and maintenance (table)

| Material | Typical Use | Durability (Years) | Maintenance | Relative Cost |

|---|---|---|---|---|

| Galvanized Steel (powder-coated) | Posts, frames | 15–30+ | Periodic coating inspection, touch-up | Medium |

| Stainless Steel (304/316) | Slides, climbing hardware | 25–40+ | Low (cleaning) | High |

| HDPE / Rotomolded Plastic | Slides, panels | 10–20 | Cleaning, check UV degradation | Medium |

| Fiberglass (FRP) | Themed facades, tunnels | 10–25 | Inspect for crazing, repair gelcoat | Medium-High |

| Poured-in-Place Rubber (EPDM) | Safety surfacing | 8–15 | Clean, repair seams | High (installation cost) |

| Engineered Wood | Theming, beams | 5–15 | Sealing, check rot | Low-Medium |

Standards and testing that validate material choices for commercial playground equipment

Compliance with recognized standards proves material suitability and installation safety. Key references include:

- ASTM F1487 — Standard Consumer Safety Performance Specification for Playground Equipment for Public Use.

- ASTM F1292 — Impact attenuation of surfacing materials for playgrounds.

- CPSC Public Playground Safety Handbook — widely referenced guidance for U.S. installations.

- EN 1176 — European standard for playground equipment.

When procuring equipment, request test reports and certificates for materials (e.g., galvanizing thickness, powder coat salt spray testing, UV resistance testing for plastics, HIC tests for surfacing). These documents make performance claims verifiable.

Inspection, maintenance schedules, and lifecycle cost planning for commercial playground equipment

Durability isn’t only a function of initial material selection—inspection and maintenance have outsized impacts on lifetime cost. Recommended practices:

- Daily/weekly: visual inspection for hazards (sharp edges, broken parts, protruding hardware) depending on usage.

- Quarterly: check fasteners, coating integrity, surface drainage, and surfacing depth or compression.

- Annual: professional structural inspection, HIC re-testing for surfacing after major repairs, and re-coating schedules as needed.

Budget life-cycle costs rather than capital cost alone. For example, stainless steel or hot-dip galvanized structures may cost more upfront but reduce repainting and replacement expenses over a 20-year term.

Design strategies to enhance durability of commercial playground equipment

Good design reduces maintenance: specify self-draining components, minimize horizontal ledges where water and debris collect, use continuous welded joints or sealed connections to prevent moisture ingress, and avoid dissimilar metals in direct contact to reduce galvanic corrosion. Consider modularity—replaceable panels or components speed repairs and minimize downtime.

Sustainability and recyclability considerations for playground materials

More operators now consider end-of-life and recycled content. HDPE is widely recyclable and many vendors offer panels with post-consumer recycled content. Metal structures are highly recyclable at end-of-life. When specifying materials, ask for recycled content percentages, recyclability statements, and environmental product declarations (EPDs) where available.

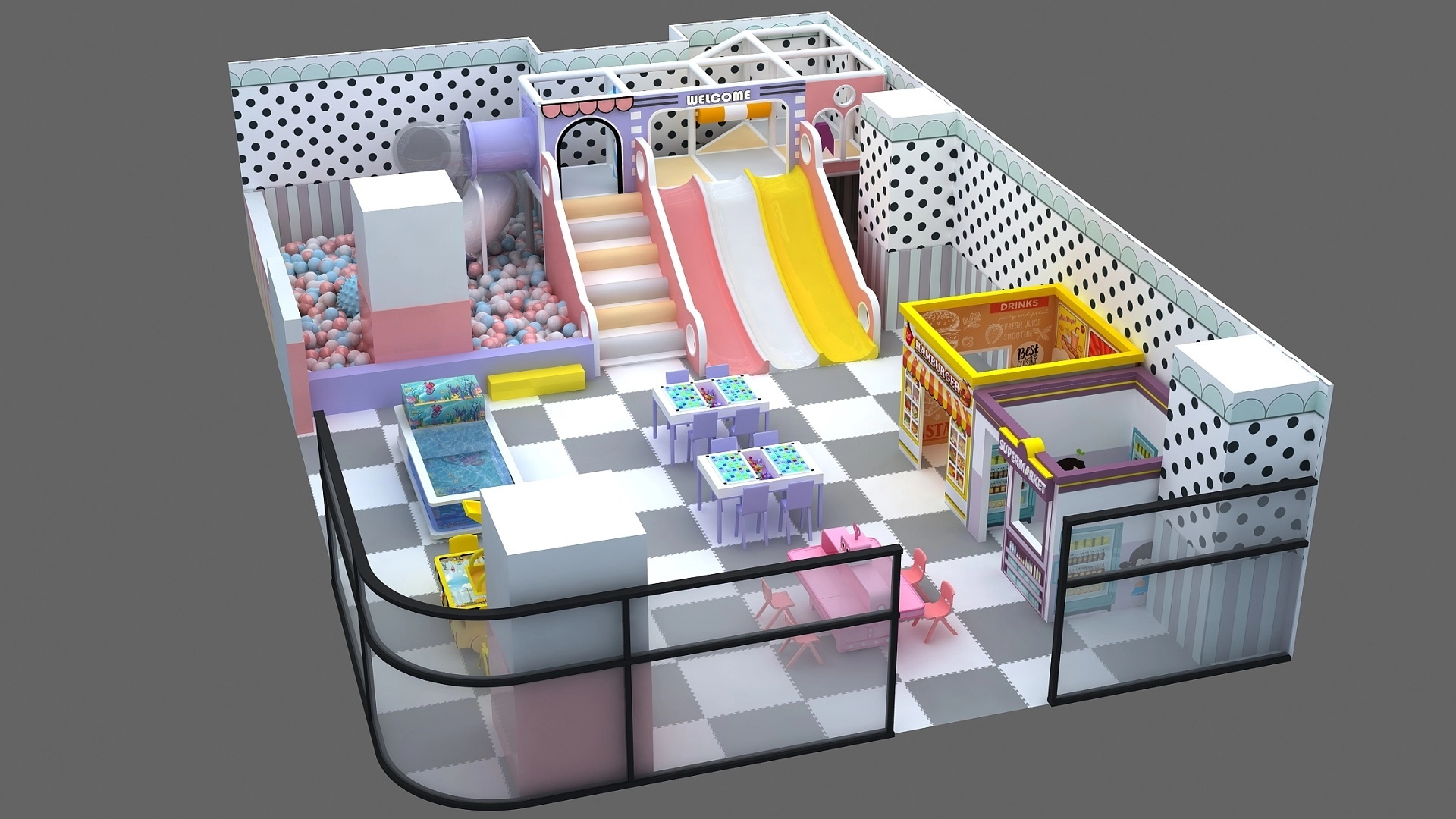

Case study summary: Selecting materials for an indoor commercial playground

Indoor commercial playgrounds have different material priorities than outdoor installations. Corrosion from weather is less of a concern, allowing use of non-galvanized steels with quality coatings. Key indoor priorities include flame retardancy, indoor air quality (low-VOC finishes), impact attenuation, and ease of cleaning (antimicrobial surfaces, smooth plastics). Specifying anti-microbial-treated fabrics for soft play and closed-cell foams for climbing elements improves hygiene and reduces maintenance in high-traffic indoor settings.

Why supplier capability matters — Introducing Guangzhou Feifan (FEI FAN)

Choosing a manufacturer with integrated design, R&D, production, and service capability improves material selection, quality control, and after-sales support for commercial playground equipment. Guangzhou Feifan Amusement Equipment Co., Ltd. (FEI FAN) was established in 2017 and operates a modern facility with a 6400 m² factory and a 5800 m² office building. FEI FAN’s main products include indoor playgrounds, trampoline park equipment, and outdoor amusement equipment. The company emphasizes high-end design, manufacturing standards, and global service.

FEI FAN advantages relevant to material durability and design:

- Integrated R&D and manufacturing allow material testing and close QA control across metalwork, plastics, and surfacing.

- Custom solutions: ability to engineer galvanization plus powder coat systems, select stainless alloys for coastal sites, and specify UV-stabilized plastics for outdoor color retention.

- Comprehensive offerings: indoor playgrounds, trampoline parks, and indoor theme parks—allowing single-source procurement for multi-zone projects.

- Global export experience and reputation for quality give confidence in meeting standards such as ASTM and EN.

FEI FAN positions itself not only as a manufacturer but as a creator of joyful experiences, enabling parent-child interaction and contributing to child development through reliable, safe, and attractive play spaces.

How to evaluate suppliers of commercial playground equipment on materials and durability

Checklist for procurement teams:

- Request materials certificates, galvanizing reports, powder coat salt spray test reports, and UV resistance data.

- Ask for HIC/surfacing test reports and installation photos of completed projects in similar climates.

- Confirm warranty scope and post-installation support: does the supplier offer inspection services or spare parts kits?

- Get references and visit installations if possible to observe long-term performance.

FAQs — Materials and Durability of Commercial Playground Equipment

1. What materials make commercial playground equipment last the longest?

Galvanized steel with quality powder coating and stainless steel in high-corrosion zones provide the longest structural life. Combined with UV-stabilized HDPE for components and poured-in-place EPDM for surfacing, this combination balances durability and user safety.

2. How often should playground equipment be inspected for material degradation?

Visual inspections should be done weekly to monthly depending on usage. Detailed inspections including structural checks and surfacing HIC testing should be annual or after severe weather events.

3. Are plastic slides and panels suitable for outdoor commercial playground equipment?

Yes—HDPE and rotomolded plastics are commonly used. Ensure UV stabilizers and pigments are specified; expect 10–20 years of service depending on climate and maintenance.

4. What surfacing material provides the best balance of safety and maintenance?

Poured-in-place rubber (EPDM) and high-quality rubber tiles provide reliable impact attenuation and accessibility with lower maintenance than loose-fill materials. They are more expensive to install but offer consistent performance and lower upkeep.

5. Should I prioritize upfront cost or lifecycle cost when choosing materials?

Lifecycle cost is generally the better metric for commercial playground equipment—higher upfront investments in corrosion-resistant metals and durable surfacing often reduce total costs over 10–20 years by minimizing repairs, downtime, and replacements.

6. How do environmental conditions affect material choice?

Coastal salt air, high UV exposure, humid climates, and heavy snowfall all influence material selection. For example, coastal sites often require 316 stainless steel or enhanced galvanization; high UV sites need UV-stable plastics and lighter colors to reduce heat buildup.

Contact and next steps

If you are specifying, upgrading, or procuring commercial playground equipment and want expert guidance on materials, durability, or a turnkey playground solution, contact Guangzhou Feifan Amusement Equipment Co., Ltd. (FEI FAN). FEI FAN offers professional design, high-quality manufacturing, and fully customized services to deliver one-stop indoor and outdoor playground solutions worldwide. Reach out to discuss site-specific material recommendations, lifecycle cost estimates, and modular design options.

References

- CPSC Public Playground Safety Handbook — U.S. Consumer Product Safety Commission. https://www.cpsc.gov/Safety-Education/Safety-Guides/Playgrounds (accessed 2025-12-20)

- ASTM F1487 — Standard Consumer Safety Performance Specification for Playground Equipment for Public Use. ASTM International. https://www.astm.org/Standards/F1487.htm (accessed 2025-12-20)

- ASTM F1292 — Standard Specification for Impact Attenuation of Surface Systems Under and Around Playground Equipment. ASTM International. https://www.astm.org/Standards/F1292.htm (accessed 2025-12-20)

- EN 1176 — Playground equipment and surfacing — European Committee for Standardization. https://standards.cen.eu/dyn/www/f?p=204:110:0::::FSP_PROJECT:59338&cs=1E6E64B0B1CC86C9A0A8B8C1B19D3A9A (accessed 2025-12-20)

- Galvanizing and corrosion resources — American Galvanizers Association. https://www.galvanizeit.org/ (accessed 2025-12-20)

- Material properties for HDPE and plastics — MatWeb Material Property Data. https://www.matweb.com/ (accessed 2025-12-20)

- FEI FAN company overview — Guangzhou Feifan Amusement Equipment Co., Ltd. internal profile and product descriptions (company materials, 2017–2025).

For personalized material recommendations, product catalogs, or a site assessment, contact FEI FAN and let experienced playground engineers help you build safer, longer-lasting play environments.

Cost to Install Soft Indoor Playground Equipment: Budget Guide

Emergency Preparedness in Indoor Play Facilities

Top Indoor Playground Equipment Trends in 2025

Best kids soft playground manufacturers and supplier brands in China

Schools Educational Institutions

Do you provide maintenance after installation?

Yes, we offer long-term after-sales service, including maintenance, spare parts, and technical support.

For Company

Do you have your own factory?

Yes, we have a modern factory building of 6400m² and a 5800 m² office building.

OEM & ODM

What certifications do your custom products have?

Our products meet international standards such as ISO, CE, GS, and more.

Shopping MallsRetail Centers

How long does it take to complete a project?

Depending on project size, design and production usually take 4–8 weeks, followed by delivery and installation.

Theme park

Do you have your own factory?

Yes, We have our own indoor children's playground production factory.Technical exchanges more convenient and faster.we can produce new product for you.

Get in touch

Let’s Build Your Dream Indoor Playground Together

Thank you for your interest in our products and services!

We’re dedicated to providing you with the best possible support and solutions for your needs.

© 2025 Feifan Amusement Equipment. All Rights Reserved.

Scan QR Code

Scan QR Code

Indoor Soft Playground

Whatsapp: +8619068970573

Scan QR Code