How to clean and maintain soft play equipment safely?

How to clean and maintain soft play equipment safely?

Operators, facility buyers and specifiers of custom indoor playgrounds must balance infection control, visitor safety, equipment longevity and warranty compliance. Below are the most-asked questions and clear, actionable answers designed for purchasing teams, facilities managers and operations staff in the custom indoor playground industry.

1. How often should soft play equipment be cleaned and disinfected?

- Daily: Quick visual wipe of high-touch points (slides, handrails, tunnel entrances, foam block edges, ball-pit rims) with a compatible cleaner; remove visible soil, spills and sticky residues.

- Weekly: More thorough wipe-down of all vinyl-covered foam surfaces, mats and seating in medium-traffic facilities. Clean and disinfect ball-pit balls on a weekly schedule for high-traffic sites; monthly for lower-traffic sites.

- Monthly / Quarterly: Deep clean of the entire soft-play structure (remove covers where possible, clean internal frames and gaps), inspect seams, fastenings, nets and anchorage points. Perform a documented deep-clean (including drying time) at least quarterly for busy commercial venues.

Rationale: Routine frequency should scale with occupancy and risk. High-traffic commercial venues (daycares, family entertainment centers) require more frequent cleaning than low-use corporate or private installations.

2. Which cleaning agents and disinfectants are safe to use on foam, vinyl and plastic components?

- Start with manufacturer recommendations: Always follow the equipment manufacturer’s cleaning instructions. Many warranties require approved products or methods.

- Mild detergent + water: First remove soil with a dilute mild detergent and water; this is safest for vinyl surfaces and foam covers.

- Disinfectants: Use EPA-registered disinfectants (or your regional equivalent) suitable for use on non-porous surfaces. For general viral disinfection, 0.1% (1000 ppm) sodium hypochlorite or EPA-registered quaternary ammonium formulations are commonly recommended—BUT check vinyl compatibility.

- Bleach caution: Sodium hypochlorite (bleach) can discolor or degrade vinyl and some foam over time. If bleach is used, test an inconspicuous area first, rinse thoroughly and ensure full drying.

- Avoid: Abrasive cleaners, solvents (acetone, paint thinners) and strong alkaline cleaners that can damage vinyl coatings, seams and printed graphics.

3. How should ball pits and soft-play balls be cleaned safely?

- Routine removal and cleaning workflow:

- Empty ball pit and sweep/vacuum the pit floor (remove debris and any foreign objects).

- Wash the balls in a washer or dedicated ball-washing machine where available (many commercial venues use ball washers that spray detergent and disinfectant, then dry the balls).

- If washing by hand: soak in warm water with mild detergent, scrub if needed, rinse and then disinfect with an approved solution (follow disinfectant contact time). Air-dry completely before returning to pit to avoid mold growth.

- Sanitation frequency: weekly for high-use sites; monthly for lower-use. Spot-clean as needed.

- Pit base and structure: Clean and disinfect the pit liner/floor and internal walls during each ball wash cycle. Ensure ventilation and drying to prevent odors and microbial growth.

4. What should be included in a routine inspection and maintenance checklist?

Daily (visual):

- Check for loose stitching, torn vinyl, exposed foam or sharp edges.

- Ensure fastenings, buckles and nets are intact and secure.

- Remove hazards and foreign objects from the play surface and ball pits.

Weekly:

- Test stability of freestanding structures and anchor points.

- Inspect seams, zippers and Velcro for wear; clean and lubricate zips if needed.

Monthly / Quarterly:

- Full structural inspection (connectors, welds, frames) — consider a trained technician for critical checks.

- Record measurements of wear (thinning vinyl, compressive set in foam). Keep photographic records and maintenance logs.

Replacement triggers: exposed foam cores, tears that expose internal fire retardant layers, permanent deformation of foam that reduces protective cushioning, or fasteners that no longer meet manufacturer torque/tension specifications.

5. How do you repair small vinyl tears or foam damage, and when should you replace components?

- Small vinyl tears: Immediate temporary repair with industry-grade vinyl repair kits (patch + adhesive) to prevent dirt ingress. Follow up with a permanent manufacturer-approved patch or replacement panel.

- Seams & stitching: Minor seam separation can sometimes be re-sewn by an upholstery technician. Larger seam failures or repeated sewing on the same seam typically indicate replacement.

- Foam cores: If foam no longer regains shape, shows permanent compression, or the protective barrier is breached, replace the foam unit. Compromised cushioning increases injury risk and should not be returned to service.

- When to replace whole modules: When multiple repairs accumulate, or when material fatigue compromises safety features (for example, exposed internal supports), plan phased replacement rather than continuous patching.

6. How should cleaning and maintenance practices be documented and how does that affect compliance and warranties?

- Keep written SOPs: Create a cleaning and maintenance Standard Operating Procedure (SOP) that includes products, concentrations, contact times, PPE, frequencies and responsible staff roles.

- Maintain logs: Daily cleaning checklists, incident and repair logs, inspection reports and photos should be retained for regulatory inspections and warranty claims.

- Training: Train staff using the SOPs and retain training attendance records. For high-risk settings, annual refresher training is recommended.

- Warranties: Many manufacturers require documented maintenance and the use of approved cleaners. Failure to follow those requirements may void parts of the warranty; always confirm requirements at purchase and include cleaning compatibility in procurement specs.

7. What regulatory standards, materials tests and certifications should buyers check when procuring custom indoor playgrounds?

- Toy & material safety: For components that behave like toys or child products, check EN 71 (European toy safety standards) or ASTM F963 (U.S. toy safety standard) and relevant local regulations for chemical migration and flammability.

- Playground equipment standards: For some indoor structures, EN 1176 (European playground equipment standard) and ASTM standards for impact attenuation may be relevant for public-facing installations. Confirm which standards apply in your jurisdiction.

- Fire & flammability: Verify that foam and covers meet local fire-retardancy requirements for public assembly spaces. Manufacturers should provide test certificates.

- Cleaning compatibility: Include manufacturer cleaning instructions and approved disinfectants in procurement contracts. Request maintenance manuals and spare-parts availability.

8. Are antimicrobial coatings and finishes worth using?

- Pros: Antimicrobial surface treatments can reduce microbial load between routine cleanings and may help reduce odors and visible soiling.

- Cons and cautions: Antimicrobial coatings are not substitutes for routine cleaning and can give a false sense of security. Efficacy varies by product and over time; durability and reapplication schedules should be verified. Also check regulatory approvals and whether coatings impact recyclability or replacement options.

Practical SOP template (quick start)

1) Daily opening checklist (approx. 15–30 mins): visual inspection, spot-clean high-touch areas, empty and secure trash, check ball-pit rim and entrance.

2) Weekly deep-clean (2–4 hours depending on size): detergent wash of vinyl, disinfect per label, clean ball pit balls, air-dry, detailed inspection, complete log.

3) Monthly technician check: structural fasteners, anchors, frame welds, replace worn components, update inventory of spare parts.

Always record product used (brand, dilution), batch/lot number for disinfectants where applicable, staff initials and start/finish times. Keep MSDS/SDS for all chemicals on-site.

Purchasing guidance for custom indoor playground buyers

- Specify easy-clean materials: Commercial-grade, flame-retardant vinyl with smooth surfaces and minimal seams reduces cleaning time and microbial harborage.

- Modularity & spare parts: Design modules to be replaceable and with removable covers when possible to speed repairs and deep-cleaning.

- Ask for manufacturer maintenance documents: SOPs, approved cleaning chemicals, recommended frequencies and training resources should be part of the contract.

- Warranty & service-level agreements: Ensure warranty specifies unacceptable cleaners, required maintenance and response times for repairs or parts supply.

- Design for service access: Include inspection access points and venting to reduce moisture build-up and mold risk.

Final checklist before putting a new custom soft-play area into service

- Obtain all safety and materials certificates (EN/ASTM or local equivalent).

- Confirm approved cleaning & disinfectant list and document any cleaning restrictions.

- Train staff on the SOP and cleaning logs; perform a supervised first deep-clean and inspection.

- Stock spare parts and repair kits and schedule quarterly technician inspections.

FEI FAN — Brand advantages summary

FEI FAN positions itself as a partner for custom indoor playground projects by focusing on: durable, easy-to-clean material choices; modular designs that allow rapid replacement of high-wear components; delivery of maintenance documentation and staff training; and warranty and spare-parts support to minimize downtime. For purchasers, these characteristics reduce total cost of ownership, simplify compliance and make daily operations safer and more efficient.

Sources

- Centers for Disease Control and Prevention (CDC), Cleaning and Disinfecting Your Facility — guidance for childcare and community settings (accessed 2024-06-01). https://www.cdc.gov/coronavirus/2019-ncov/community/disinfecting-building-facility.

- U.S. Environmental Protection Agency (EPA), List of Disinfectants (EPA List N and disinfectant registration information) — guidance on approved disinfectants and contact times (accessed 2024-06-01). https://www.epa.gov/pesticide-registration/list-n-disinfectants-use-against-sars-cov-2

- World Health Organization (WHO), Cleaning and disinfection of environmental surfaces in the context of COVID-19 — practical recommendations for disinfectant concentrations (accessed 2024-06-01). https://www.who.int/publications/i/item/WHO-2019-nCoV-Disinfection-2020.1

- Kompan / Play equipment manufacturer maintenance and cleaning resources — manufacturer technical maintenance recommendations and inspection schedules (accessed 2024-06-01). https://www.kompan.com and https://www.playcore.com (technical resources pages)

- European Standards (EN 71) and playground equipment standards (EN 1176) — safety and material testing references for buyers (accessed 2024-06-01). https://www.cen.eu and https://www.bsigroup.com

- U.S. Consumer Product Safety Commission (CPSC), toy & playground safety resources — guidance on material safety and recalls (accessed 2024-06-01). https://www.cpsc.gov

How to Reasonably Control Costs of Kids Indoor Playgrounds | Trusted Manufacture

Flourishing in Both the Middle East and Europe! What Makes Guangzhou Feifan Amusement a Leading Export Manufacturer of Indoor Playgrounds?

What Is an IP Indoor Playground & Its Core Benefits? | Insight by Feifan

From Concept to Operation: How to Achieve High Foot Traffic for Your Indoor Playground?

Indoor Playgrounds Trampoline Parks

How long does it take to complete a project?

Depending on project size, it typically takes 4–10 weeks from design to delivery and installation.

Shopping MallsRetail Centers

How much space is required to set up an indoor playground?

Our equipment is highly flexible and can be customized for both large atriums and compact spaces as small as 50–100 m².

For Products

What are the mainly themes of indoor playground ?

Various themes including space series, forest series, macaroon series, ocean series, candy series, etc

OEM & ODM

How long is the the production time of customized themes?

It depends on the size and design of the projects , it takes about 15-45 days.

Schools Educational Institutions

How much space is required for installation?

We provide flexible designs that fit both small courtyards and large campus grounds, fully optimized for your available area.

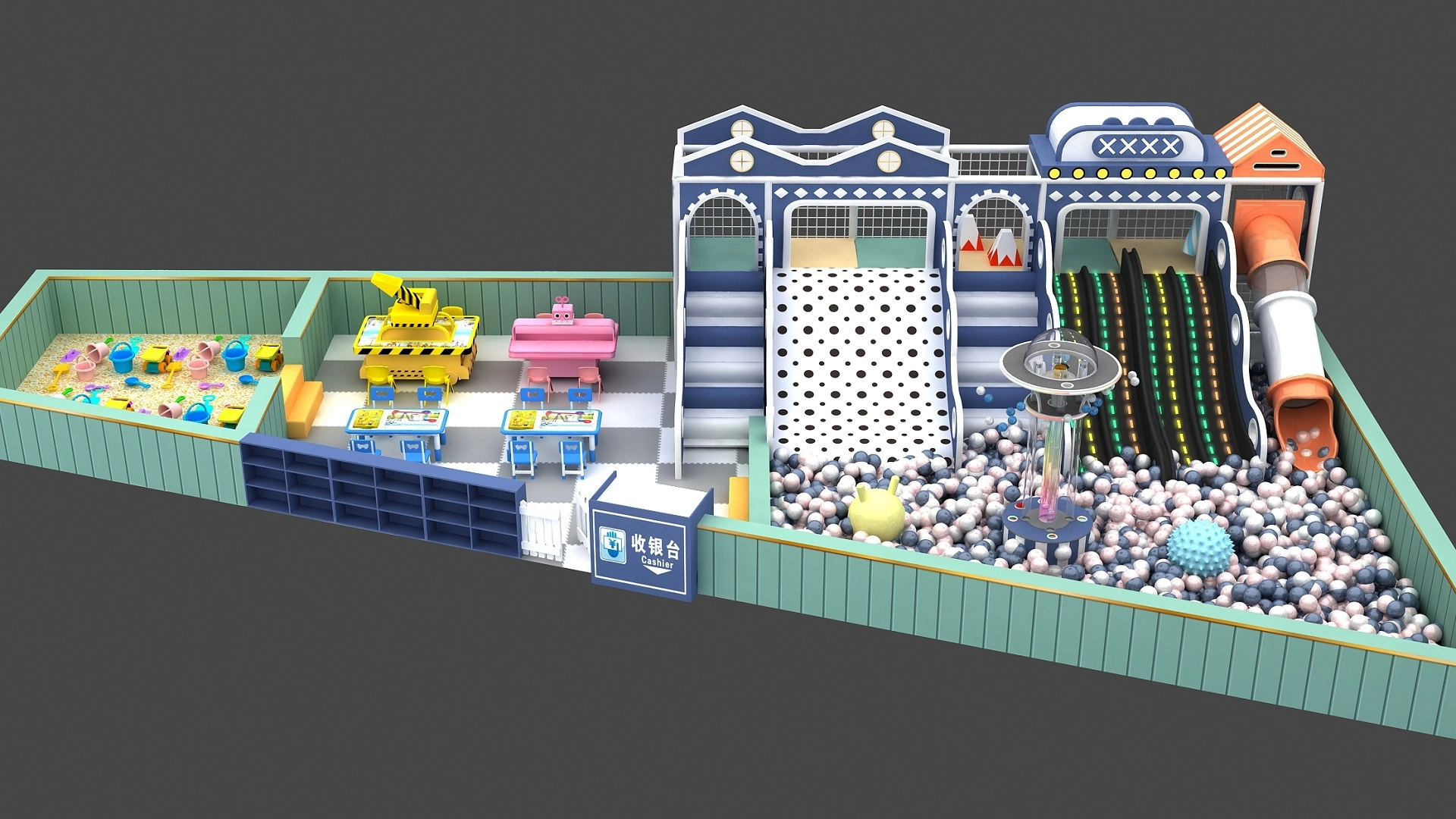

FEI FAN’s New Style Indoor Amusement Equipment offers custom toddler soft play solutions designed for safety and fun. Ideal for baby parks, this safe-friendly play equipment enhances indoor amusement spaces with durable, engaging designs parents trust. Perfect for early childhood development.

Send my request

Let’s Build Your Dream Indoor Playground Together

Thank you for your interest in our products and services!

We’re dedicated to providing you with the best possible support and solutions for your needs.

© 2025 Feifan Amusement Equipment. All Rights Reserved.

Scan QR Code

Scan QR Code

Indoor Soft Playground

Whatsapp: +8619068970573

Scan QR Code