What materials are used in soft play equipment?

Materials Used in Soft Play Equipment: What Buyers of Custom Indoor Playgrounds Need to Know

Buying custom indoor playground equipment requires both design sense and technical due diligence. This guide answers the most frequent procurement questions about materials used in soft play so you can specify, evaluate and accept equipment that is safe, durable, cleanable and legally compliant.

1. What are the core materials used in soft play equipment?

Soft play items are assemblies combining a foam core, a protective cover, and sometimes internal structural elements. Common components are:

- Foam cores — Expanded Polyethylene (EPE), Expanded Polypropylene (EPP), and molded Polyurethane (PU) foams are the industry staples. They provide impact attenuation and shape. EPE/EPP are closed-cell and resist water; PU is used for shaped cushions.

- Covers — PVC-coated polyester (vinyl) is the most widely used cover fabric because it is wipeable, durable and available with flame-retardant treatments. Heavy-duty vinyl (e.g., 600–1200 denier polyester base with PVC or PU coating) is typical.

- Structural panels and frames — Plywood, MDF/OSB with edge protection, or HDPE panels are used for play panels, climb frames and boxed elements. Metal (galvanized or powder-coated steel) is used in load-bearing frames where required.

- Fasteners and fittings — Industrial zippers, heavy-duty Velcro (hook-and-loop), nylon/polyester webbing, stainless steel fixings and foam adhesives are common.

- Flooring — Interlocking EVA foam tiles, closed-cell foam mats, or commercial-grade vinyl-encased foam mats are typical for indoor soft play surfaces. For fall zones, playground rubber or poured-in-place surfacing may be used depending on the design.

- Nets and textiles — Nylon or polyester netting, rope, and soft fabrics for padding and soft obstacles.

2. How do I evaluate foam types and which properties matter?

When specifying foam, focus on impact attenuation, resilience, dimensional stability and water resistance. Procurement checks should include:

- Foam type — EPE and EPP are preferred where water resistance and closed-cell behavior are needed; PU is frequently used for shaped seating and steps where high cushioning and shaping are required.

- Density and firmness — Suppliers should provide foam density (kg/m3) and indentation/load-deflection data. These figures predict durability and energy absorption — ask for test reports from the manufacturer.

- Compression set and resilience — Low compression set is desirable for items that will see repetitive loading (e.g., landings and seats).

- Water absorption — For indoor play that needs frequent cleaning or occasional wetting, closed-cell foams (EPE/EPP) perform better.

Request technical datasheets and sample pieces, and, if possible, independent lab test results for impact attenuation and density.

3. What coverings and finishes are best for durability, hygiene and indoor cleaning?

Cover selection balances durability, cleanability and user safety. Key considerations:

- PVC-coated polyester (vinyl) — Most common. It is wipe-clean, available with flame retardant treatments, and offered in many colors and textures. Ensure the vinyl is phthalate-free and certified for use in children’s products in your market.

- Coating weight and fabric denier — Heavier coatings and higher denier polyester bases increase abrasion resistance. For heavy commercial use, specify industrial-grade vinyl (e.g., 600 denier base or higher with robust PVC coating).

- Seams and fastenings — Welded seams are more water-resistant than sewn seams; double-stitched, reinforced seams and heavy-duty zippers or Velcro increase longevity.

- Antimicrobial and stain-resistant options — Some covers have antimicrobial finishes (e.g., silver-ion treatments) or are compatible with hospital-grade cleaning. Check manufacturer claims and ask for independent test documentation for antimicrobial efficacy and safety.

- Surface texture — Non-slip textures are useful for ramps and platforms; smooth vinyl is easier to disinfect.

Specify cleaning-compatible covers and get supplier cleaning instructions to avoid damaging coatings with harsh chemicals.

4. Which safety, fire and chemical standards should I require from suppliers?

Regulatory obligations depend on your country, but ask suppliers for evidence of compliance with international and regional standards commonly referenced by buyers:

- Toy and children’s product safety — EN 71 series (EU), ISO 8124 (international) or local equivalents. EN 71‑3 addresses migration of certain elements (heavy metals) from materials used in toys.

- Flammability — Relevant tests include national furniture and upholstery flammability standards (e.g., BS 5852 in the UK for upholstered furniture). Many indoor play providers ask for vinyl coverings and foams with recognized fire performance and vendor test reports.

- Chemical restrictions — REACH (EU) and CPSIA (US) limit certain phthalates, lead and other restricted substances in children’s products. Request declarations of conformity and laboratory test reports (e.g., EN 71‑3, REACH SVHC checks, CPSIA phthalate/lead tests).

- Playground surfacing and fall attenuation — For fall zones around elevated play elements, standards or test methods such as ASTM and EN standards for impact attenuation of surfacing should be referenced (ask for test certificates when surfacing is supplied as part of the package).

Always require material test certificates (lab reports) tied to the specific production lot, not just manufacturer brochures.

5. What cleaning and maintenance practices are recommended for soft play materials?

Hygiene is crucial for indoor play spaces. Best practices:

- Daily cleaning — Wipe high-touch vinyl surfaces with a mild detergent solution. Use a soft cloth; avoid abrasive brushes.

- Disinfection — Follow public-health guidelines for disinfectants. For general disinfection, diluted bleach solutions or EPA-registered disinfectants are commonly recommended, but confirm compatibility with vinyl and foam (some disinfectants can degrade PVC or printed coatings). Many operators use 0.1% sodium hypochlorite (bleach) or alcohol-based products for high-risk contamination, applied per label directions.

- Manufacturer’s instructions — Always follow supplier cleaning specifications to avoid invalidating warranties. Ask suppliers to confirm which cleaning agents are safe.

- Deep cleaning and repair — Schedule periodic deep cleanings (steam cleaning where safe for materials) and inspect seams, zippers and foam for wear. Keep repair kits (patch vinyl, replacement covers) for rapid fixes.

Document cleaning protocols and train staff. For outbreak response, have a written disinfection plan and materials on hand.

6. What environmental and health factors should be considered (phthalates, VOCs, recyclability)?

Buyers increasingly demand safer and more sustainable materials. Key points to verify:

- Phthalate- and lead-free — Request test certificates (CPSIA, REACH) showing restricted substances are below legal limits.

- Low-VOC materials — Vinyl and adhesives can emit volatile organic compounds (VOCs). Ask for material VOC emission data or certifications such as Greenguard, which indicate low emissions.

- Recyclability and end-of-life — Closed-cell foams and mixed-material assemblies are harder to recycle. Ask suppliers about take-back programs, separable covers vs. bonded foam, and the use of recyclable HDPE panels where possible.

- Certifications — Look for third-party certifications (OEKO‑TEX for textiles, Greenguard for low emissions) and supplier environmental statements.

7. What installation, warranty and lifecycle-cost issues should buyers inspect?

Total cost of ownership matters more than initial price. When procuring custom indoor playgrounds, examine:

- Installation scope — Clarify if price includes site survey, subfloor preparation, anchoring, mechanical fixings and installation labor. Improper anchoring is a common source of safety issues.

- Serviceability and modularity — Modular designs allow replacement of high-wear panels and covers rather than whole elements. Ask for spare-part availability and lead times.

- Warranty and post-install support — Check coverage for seams, zippers, foam compression, and structural elements. Ask about expected usable life (typical commercial indoor play installations often see 5–10 years of service depending on traffic) and maintenance obligations that affect warranties.

- Testing and handover — Require a final inspection checklist and as-built documentation. Where relevant, request impact attenuation test reports for surfacing, and certificates of conformity for installed items.

8. What are the main cost drivers and how to optimize specification without compromising safety?

Major cost drivers include foam density and volume, heavy-duty or flame-retardant vinyl, custom shaping and CNC cutting, interactive electronics, and complex structural frames. Ways to optimize:

- Use off-the-shelf modules for high-wear common elements and reserve bespoke work for signature areas.

- Specify replaceable covers and modular foam inserts so worn parts can be swapped economically.

- Balance foam density to use higher density only where required for durability (e.g., landings), while using economical foam in low-wear decorative elements.

- Request multiple material options and lifecycle cost comparisons from suppliers, including sample materials and expected maintenance costs.

Checklist of documents and tests to request from any soft play supplier

- Material datasheets for foam and covers (density, compression, water absorption, flame ratings)

- Third-party lab test reports for chemical compliance (EN 71‑3, REACH, CPSIA as relevant)

- Fire test certificates or declarations relevant to your jurisdiction (e.g., upholstery flammability tests)

- Cleaning and maintenance instructions

- Warranty terms and spare-parts availability

- Installation scope, site-prep requirements, and inspection/handover checklist

Why partner with an experienced manufacturer like FEI FAN

FEI FAN specializes in custom indoor playground solutions and stands out for several procurement-critical reasons:

- Technical documentation — FEI FAN provides detailed material datasheets, test reports and cleaning protocols to support regulatory compliance and safe operation.

- Modular, serviceable designs — Their systems emphasize replaceable covers and modular components to reduce lifecycle costs and downtime.

- Quality control and safety focus — FEI FAN applies recognized fire and chemical safety practices for children’s environments and supports customers with installation and aftercare guidance.

- Global project experience — With numerous custom projects, FEI FAN combines design flexibility with proven manufacturing processes, helping owners balance cost, durability and user experience.

For procurement teams, FEI FAN’s combination of documentation, modularity and after-sales support reduces risk and total cost of ownership for custom indoor playground projects.

References and sources

- European Chemicals Agency (ECHA) — REACH regulation and restricted substances. (echa.europa.eu) — Accessed 2026-02-03

- U.S. Consumer Product Safety Commission (CPSC) — Children's product safety guidance including CPSIA phthalate/lead limits. (cpsc.gov) — Accessed 2026-02-03

- EN 71 series and toy safety guidance — BSI/European standards information on safety of toys (EN 71‑3). (bsigroup.com / CEN references) — Accessed 2026-02-03

- World Health Organization / Centers for Disease Control (WHO, CDC) — Cleaning and disinfection recommendations for public spaces and environmental surfaces. (who.int, cdc.gov) — Accessed 2026-02-03

- ASTM and playground surfacing standards — Industry references for impact attenuation and surfacing (ASTM/EN standards). (astm.org) — Accessed 2026-02-03

- Guidance on furniture and upholstery flammability testing (e.g., BS 5852) — BSI and national fire-safety test standards. (bsigroup.com) — Accessed 2026-02-03

Note: When evaluating offers, request current, lot-specific test reports or certificates. Regulatory requirements and test methods differ by country, so cross-check requirements for the installation jurisdiction.

How to Reasonably Control Costs of Kids Indoor Playgrounds | Trusted Manufacture

Flourishing in Both the Middle East and Europe! What Makes Guangzhou Feifan Amusement a Leading Export Manufacturer of Indoor Playgrounds?

What Is an IP Indoor Playground & Its Core Benefits? | Insight by Feifan

From Concept to Operation: How to Achieve High Foot Traffic for Your Indoor Playground?

OEM & ODM

How long is the the production time of customized themes?

It depends on the size and design of the projects , it takes about 15-45 days.

Do you offer 3D renderings before production?

Yes, every custom project includes full 3D visualization before final approval.

Indoor Playgrounds Trampoline Parks

How long does it take to complete a project?

Depending on project size, it typically takes 4–10 weeks from design to delivery and installation.

Theme park

Can theplayground be customized?

Yes. Please send us a CAD file or a simple drawing of your play area with precise dimensions,and let us know the budget, theme and so on.

Shopping MallsRetail Centers

How much space is required to set up an indoor playground?

Our equipment is highly flexible and can be customized for both large atriums and compact spaces as small as 50–100 m².

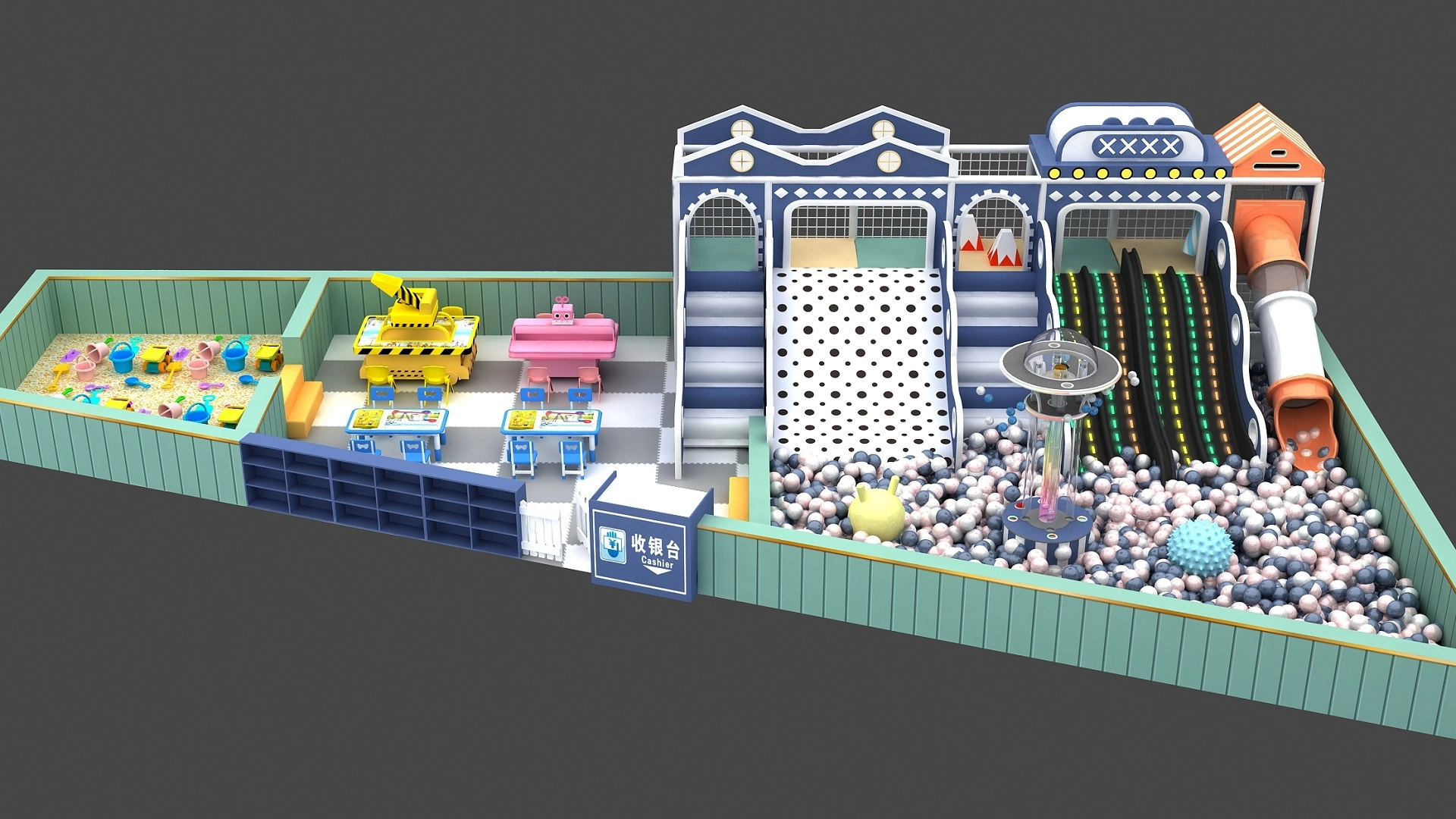

FEI FAN’s New Style Indoor Amusement Equipment offers custom toddler soft play solutions designed for safety and fun. Ideal for baby parks, this safe-friendly play equipment enhances indoor amusement spaces with durable, engaging designs parents trust. Perfect for early childhood development.

Send my request

Let’s Build Your Dream Indoor Playground Together

Thank you for your interest in our products and services!

We’re dedicated to providing you with the best possible support and solutions for your needs.

© 2025 Feifan Amusement Equipment. All Rights Reserved.

Scan QR Code

Scan QR Code

Indoor Soft Playground

Whatsapp: +8619068970573

Scan QR Code