Installation, Maintenance & Layout of Trampoline Park Equipment

Installation, Maintenance & Layout of Trampoline Park Equipment

Overview: Why correct installation of trampoline park equipment matters

Proper installation, smart layout, and disciplined maintenance of trampoline park equipment are fundamental to safety, guest experience, and long-term profitability. Whether you are opening a new facility or upgrading an existing venue, decisions about flooring, structural anchoring, equipment spacing, and recurring inspection plans directly influence accident risk, downtime, and operational cost.

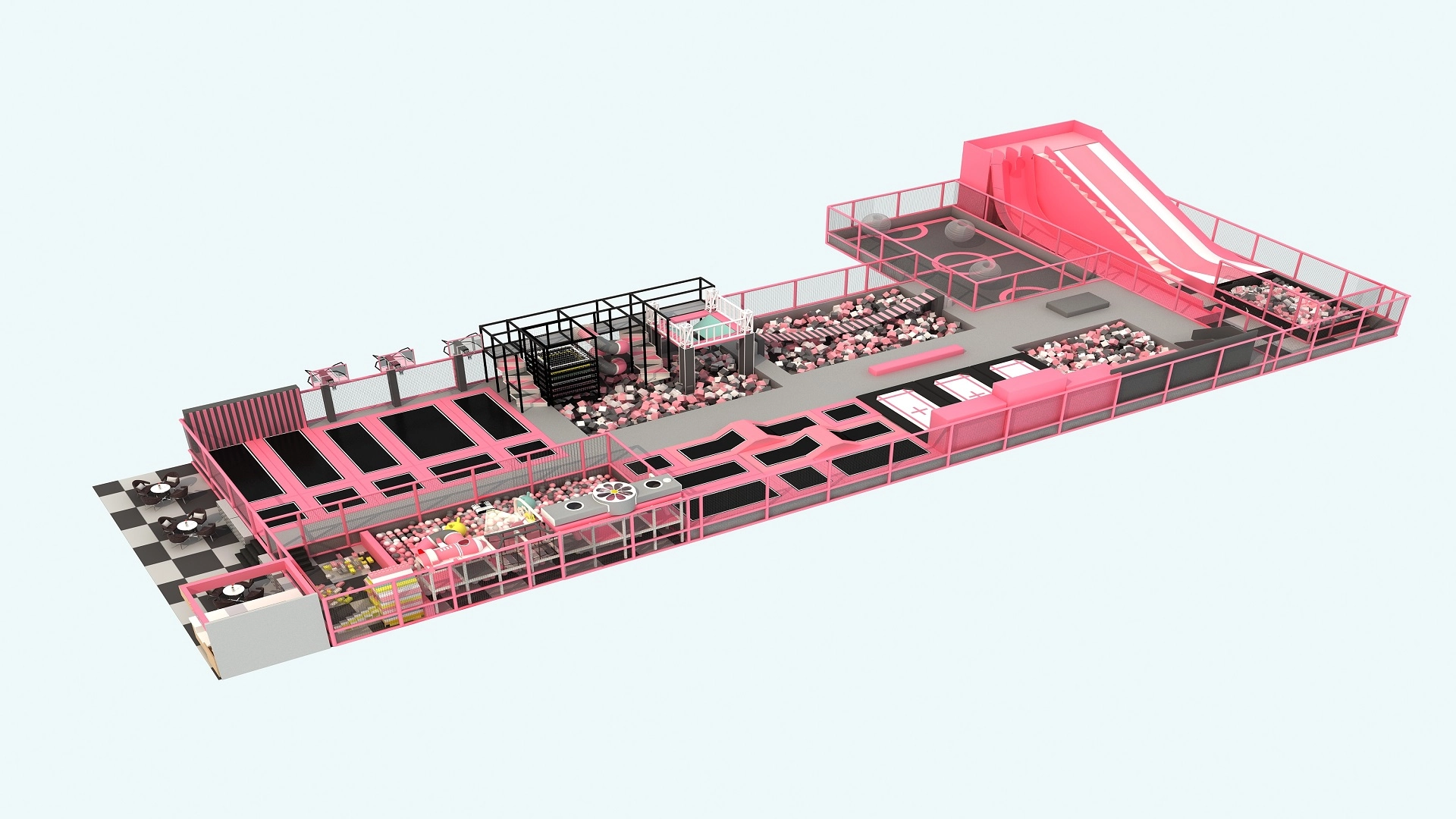

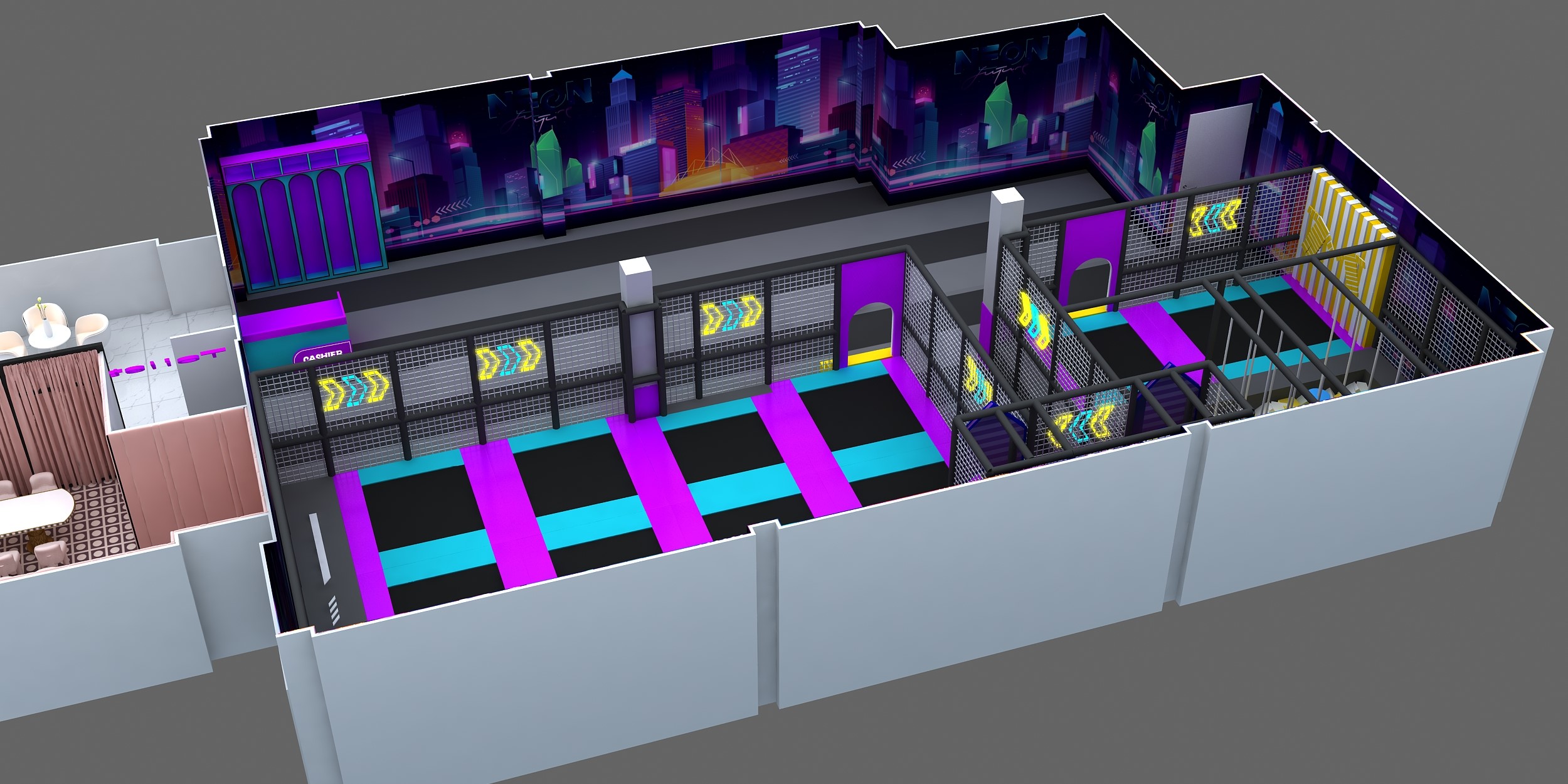

Product spotlight: Hot Sale Commercial Trampoline Park Equipment

This commercial indoor trampoline park equipment offers diverse, safe, and fun bouncing zones with slides, obstacle courses, and vibrant designs, ideal for all-age entertainment venues.

When evaluating Hot Sale Commercial Trampoline Park Equipment for installation, consider its modular components, recommended clearances, electrical and support requirements, and vendor-provided installation services. The remainder of this guide explains what those considerations mean in practice.

Site selection and pre-installation planning for trampoline park equipment

Choosing the right site reduces later complications. Key site characteristics to evaluate:

- Ceiling height: Standard trampoline courts usually require clear height of at least 5.5–8 meters (18–26 ft) depending on the activity (free-jump areas need more). Verify manufacturer minimums.

- Floor loading capacity: Confirm the building’s floor can support concentrated loads from equipment, foam pits, and anchors. Structural engineer sign-off is recommended.

- Access and logistics: Ensure adequate access for delivery, cranes/forklifts if needed, and staging areas for assembly.

- Utilities and fire safety: Check power supply for trampolines with lighting or automated systems; plan for emergency egress and sprinkler/alarm integration per local code.

Early coordination with the equipment supplier simplifies timelines. Ask for detailed equipment drawings, foundation/anchor specifications, and a full bill of materials before signing.

Foundation, flooring and substructure requirements for trampoline park equipment

Flooring and foundation choices impact safety, noise, and maintenance. Typical layers include structural slab, subflooring where required, shock-absorbing underlayment, and durable top surfacing. For trampoline park equipment you should:

- Use engineered solutions for jumping surfaces — elastic frames and jump beds are mounted on steel grid systems that require precise levelling.

- Install certified impact-attenuating foam or pads in designated fall zones and pit areas.

- Select top surfacing (rubber tiles, vinyl sports flooring) that is wear-resistant, easy to clean, and compliant with local fire codes.

Insufficient substructure or improper surfacing increases risk of injury and shortens equipment life.

Anchoring, assembly and professional installation best practices for trampoline park equipment

Always follow manufacturer instructions and use certified installers for trampoline park equipment. Recommended steps:

- Receive and verify all components against packing lists immediately on delivery.

- Assemble structural frames on level surfaces; tighten fasteners to torque specifications.

- Anchor frames to the building structure where required—do not rely on weight alone for larger modules.

- Install protective padding, netting and barriers as specified and test their effectiveness.

- Conduct a pre-opening safety audit using a checklist that covers all systems, moving parts, and clearances.

Document each step and retain signed sign-off from installation technicians and a qualified inspector.

Safety standards and regulation considerations for trampoline park equipment

Complying with recognized safety guidance protects guests and reduces legal exposure. While regulation varies by country, consult these authorities:

- ASTM International — industry guidance for trampoline park operation and design.

- IAAPA — best practices and operational recommendations for amusement facilities.

- Local building codes, fire codes and consumer safety agencies (e.g., CPSC in the U.S.).

Integrate standard operating procedures (SOPs) that reflect these guidelines into your staff training and inspection routines.

Daily and routine maintenance checklist for trampoline park equipment

Establishing a maintenance cadence prevents small issues from becoming major failures. Suggested schedules:

- Daily: Visual inspection of trampolines, nets, padding, loose bolts, debris removal, and functionality checks of entrances/exits.

- Weekly: Detailed hardware check (bolts and welds), inspection of foam pits and replacement of worn foam, testing of emergency exits and fire safety systems.

- Monthly: Structural integrity review, floor/underlayment inspection for compression or water damage, condition assessment of padding and jump beds.

- Annually: Full engineering inspection by a qualified technician, replacement of worn components per manufacturer’s lifecycle guidance.

Use digital logs to track inspections and remedial work—this provides evidence of due diligence and helps with warranty claims.

Maintenance comparison table: common components and service intervals

| Component | Daily | Monthly | Annual |

|---|---|---|---|

| Jump beds / mats | Clean, visual tear check | Measure tension, inspect stitching | Replace if tension loss or wear exceeds limits |

| Padding & covers | Check for tears, reposition | Replace foam covers showing compression | Complete replacement on heavy-use zones (as needed) |

| Nets / barriers | Inspect for holes | Secure attachment & repair small tears | Replace compromised nets |

| Frames / anchors | Visual check | Tighten fasteners | Engineering review |

Sources for recommended intervals: manufacturer manuals and industry practice. Adjust schedules based on guest volume and environmental factors.

Staffing, training and operating procedures for trampoline park equipment

People are the first line of safety. Key operational elements include:

- Certified jump attendants per zone to enforce rules, manage capacity and respond to incidents.

- Standardized training covering emergency response, equipment checks, guest interaction and cleaning protocols.

- Clear signage and communicated rules for guests — age/height restrictions, footwear policy, and single-user rules for certain zones.

Create drills (first aid, evacuation) and require staff certification (CPR/first aid). Keep an incident log and perform root-cause reviews of every injury or equipment failure.

Designing layout and traffic flow for trampoline park equipment

Good layout balances guest enjoyment, safety buffers, and revenue optimization. Design principles:

- Segmentation: Separate free-jump zones, dodgeball courts, foam pits and children’s areas to match skill levels and reduce collision risk.

- Buffers: Maintain clear run-off areas and vertical clearances. Follow manufacturer spacing recommendations between adjacent trampolines.

- Lines and queuing: Design areas for parents, waiting guests and spectator zones without obstructing emergency egress.

- Visibility: Place attendants on raised or central platforms to maintain unobstructed sightlines across activity zones.

Layout decisions influence capacity. Model expected throughput per area and compare to peak demand to avoid overcrowding.

Troubleshooting common problems with trampoline park equipment

Frequent issues and quick remedies:

- Loose bolts or noisy frames — tighten to torque spec, use threadlocker where recommended.

- Sagging jump beds — inspect stitching and mounting points; adjust tension or replace bed when beyond repair limits.

- Foam pit odor or degradation — replace foam blocks on schedule; ensure proper ventilation and cleaning.

- Damaged padding — immediate replacement or temporary area closure until fixed.

When in doubt, remove the module from service and consult the equipment manufacturer for repair parts and instructions.

Lifecycle management and parts replacement plan for trampoline park equipment

Plan for component lifecycle and spare parts inventory. Typical recommendations:

- Keep a stock of high-wear parts (padding covers, fasteners, bed springs/cords) to minimise downtime.

- Track hours of use and guest throughput to forecast replacement cycles more accurately than calendar time alone.

- Budget annually for capital refreshes — high-traffic parks often require partial upgrades every 3–5 years.

Vendor warranties vary; retain maintenance records to support claims and extend useful life via proactive service.

Brand advantages: why choose our Hot Sale Commercial Trampoline Park Equipment

When selecting equipment, our Hot Sale Commercial Trampoline Park Equipment stands out for several reasons:

- Modular design — simplified installation and future expansion with interchangeable modules that reduce downtime.

- Safety-first materials — high-density foam, flame-retardant covers, and certified nets to meet industry guidelines.

- Comprehensive installation & training — professional installation teams and staff training packages streamline opening.

- After-sales support & parts availability — stocked spare parts and scheduled maintenance plans to keep operations running.

- Customisable aesthetics — vibrant themes and signage options that support brand-building and marketing efforts.

Combining a safety-focused product with professional installation and documented maintenance practices improves guest trust and extends equipment lifespan.

FAQs — Installation, Maintenance & Layout of Trampoline Park Equipment

Q: What are the minimum clearances needed around trampoline park equipment?

A: Minimum clearances vary by equipment and manufacturer. As a rule of thumb, allow at least 1.5–2 meters (5–7 ft) between active zones and fixed structures, and ensure sufficient vertical clearance per the equipment manual. Always follow the specific clearances in the installation documentation for your Hot Sale Commercial Trampoline Park Equipment.

Q: How often should jump beds be replaced?

A: Replacement depends on use. Inspect jump beds weekly for tension loss, tears or seam separation. High-traffic parks may need to replace jump beds every 1–3 years; lower-traffic venues can often extend this. Follow manufacturer lifecycle guidance.

Q: Can we install trampoline park equipment on an older building floor?

A: Possibly, but obtain a structural assessment. Concentrated loads from frames and anchors can exceed slab capacity. A structural engineer should confirm load-bearing capacity and recommend any reinforcement.

Q: What training should attendants receive?

A: Attendants should be trained in SOP enforcement, guest safety rules, basic equipment checks, conflict de-escalation, incident reporting, and first aid/CPR.

Q: Do you provide installation services and spare parts for Hot Sale Commercial Trampoline Park Equipment?

A: Yes — professional installation, staff training and spare parts packages are available. Contact our team for customized service plans to match your venue size and expected throughput.

Contact us / View product

Ready to install safe, attractive and profitable trampoline park equipment? Contact our sales team to schedule a site assessment, request a quote for Hot Sale Commercial Trampoline Park Equipment, or arrange professional installation and training. Email us or call to view product specs and availability.

After understanding the essentials of trampoline park installation, maintenance, and layout, the next step is to explore the most popular equipment brands on the market. Compare features, quality, and customer feedback in Top Hot Sale Trampoline Park Equipment Brands Compared. This article provides detailed brand comparisons to help operators choose reliable and high-performance equipment for their parks.

References and sources

- ASTM International — Relevant standards and best practices for trampoline parks: https://www.astm.org/Standards/F2970.htm

- International Association of Amusement Parks and Attractions (IAAPA) — Safety resources and operational guidance: https://www.iaapa.org

- U.S. Consumer Product Safety Commission (CPSC) — General playground and equipment safety guidance: https://www.cpsc.gov

Top 10 Indoor Playground Manufacturers Compared

Best Flooring Options for Indoor Playgrounds: Pros and Cons

How to choose a commercial indoor trampoline supplier

Trampoline party ideas for indoor playgrounds

Indoor Playgrounds Trampoline Parks

What is the lifespan of the equipment?

With proper maintenance, our indoor playground and trampoline equipment can last 8–10 years or more.

Can I upgrade or expand my playground/trampoline park in the future?

Absolutely. Our modular design allows you to expand or reconfigure easily to meet future business needs.

Schools Educational Institutions

What is the lifespan of your equipment?

With regular maintenance, our school playground equipment can last 8–10 years or more.

For Products

How many square meters should we have to start an indoor playground ?

As usual,It is around in 50-500 square meters,For a large commercial center , it is about 500-2000 square meters.

Shopping MallsRetail Centers

Can you design amusement equipment based on our mall’s theme?

Yes, we specialize in theme customization, from ocean and jungle to branded concepts that match your retail center’s identity.

Discover FEI FAN’s top-rated trampoline park equipment at a good price. Our durable, safe trampoline park equipment for sale ensures endless fun and reliability. Choose FEI FAN for high-quality, affordable trampoline solutions designed to elevate your park experience.

Get in touch

Let’s Build Your Dream Indoor Playground Together

Thank you for your interest in our products and services!

We’re dedicated to providing you with the best possible support and solutions for your needs.

© 2025 Feifan Amusement Equipment. All Rights Reserved.

Scan QR Code

Scan QR Code

Indoor Soft Playground

Whatsapp: +8619068970573

Scan QR Code